Duasolid 50

Gloss

A two-component, high-solids oxirane ester paint containing active anti-corrosive pigments.

- Iso-cyanate free DTM product

- Good corrosion resistance

- Easy to apply

A two-component, high-solids oxirane ester paint containing active anti-corrosive pigments.

Product Features

• An option when products containing iso-cyanate cannot be used. The paint offers quality similar to that achieved with polyurethanes. • Does not compromise protection or performance. Laboratory and field testing have proved the effectiveness of Duasolid systems in providing excellent corrosion protection, both for interior and exterior service environments. • A high solids content and can be applied in thick layers, thus enabling faster production. The product is an ideal option for OEM and other steel structures, equipment and machinery. • Used as a single coat or as a topcoat in oxirane-ester based systems on steel surfaces exposed to abrasion and chemicals in severe climatic conditions. • High film-building properties, up to 100 µm / one coat. • Resistance to continuous temperature up to +80°C dry heat and temporarily up to +120°C dry heat.

Recommended Uses

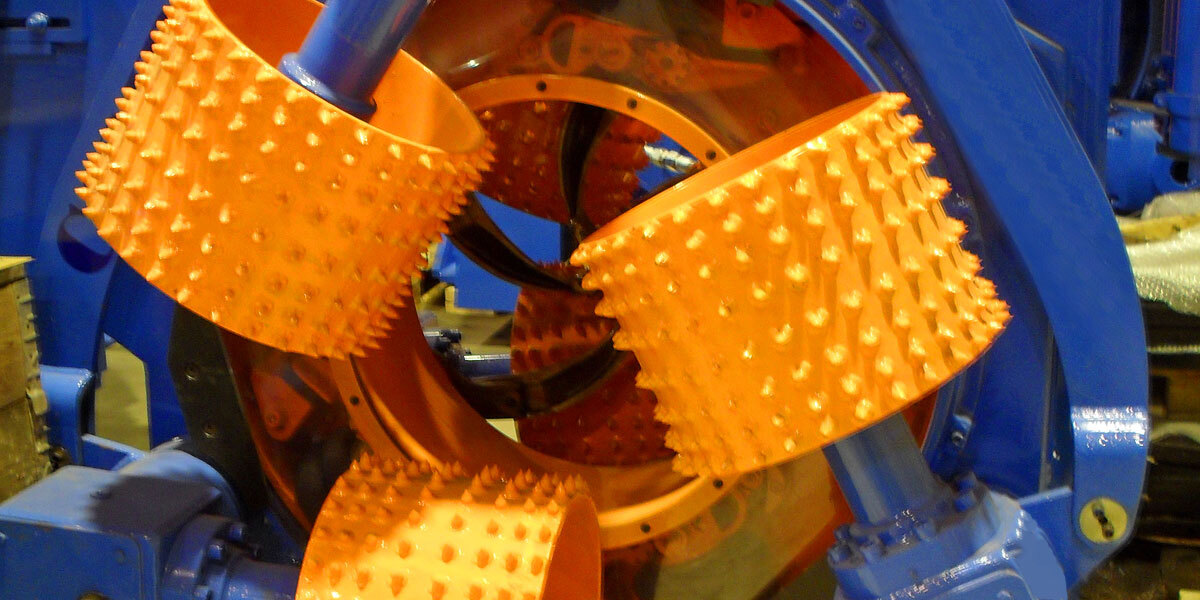

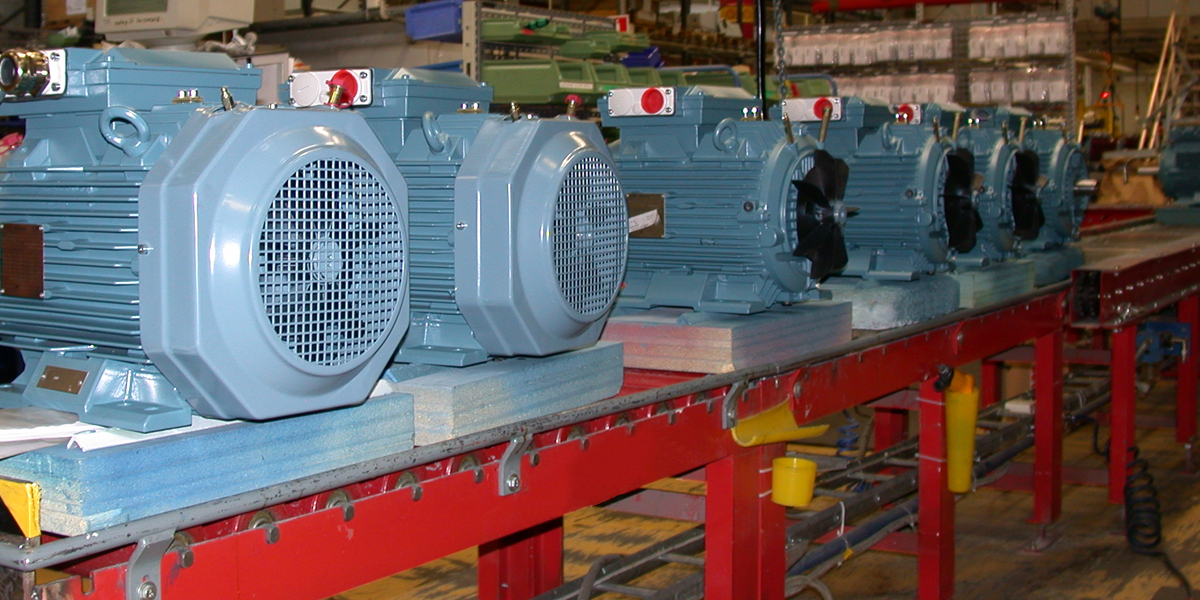

• Suitable for earth moving machines, haulage and lifting equipment, forklifts, agricultural machinery, electric appliances, pumps and other steel structures, equipment and machinery.

Iso-cyanate free DTM product

Duasolid 50 is an option when products containing iso-cyanate cannot be used. The paint offers quality similar to that achieved with polyurethanes.

Good corrosion resistance

Duasolid 50 does not compromise protection or performance. Laboratory and field testing have proved the effectiveness of Duasolid systems in providing excellent corrosion protection, both for interior and exterior service environments.

Easy to apply

Duasolid 50 has a high solids content and can be applied in thick layers, thus enabling faster production. The product is an ideal option for OEM and other steel structures, equipment and machinery.