Fontefire ST 60-1

Matt

A water-borne, thin film intumescent coating for efficient protection against cellulosic fires. When subjected to heat it expands and forms an insulating layer of foam.

- Highly competitive loadings

- Great application properties

- Suitable for semi-exposed conditions

A water-borne, thin film intumescent coating for efficient protection against cellulosic fires. When subjected to heat it expands and forms an insulating layer of foam.

Product Features

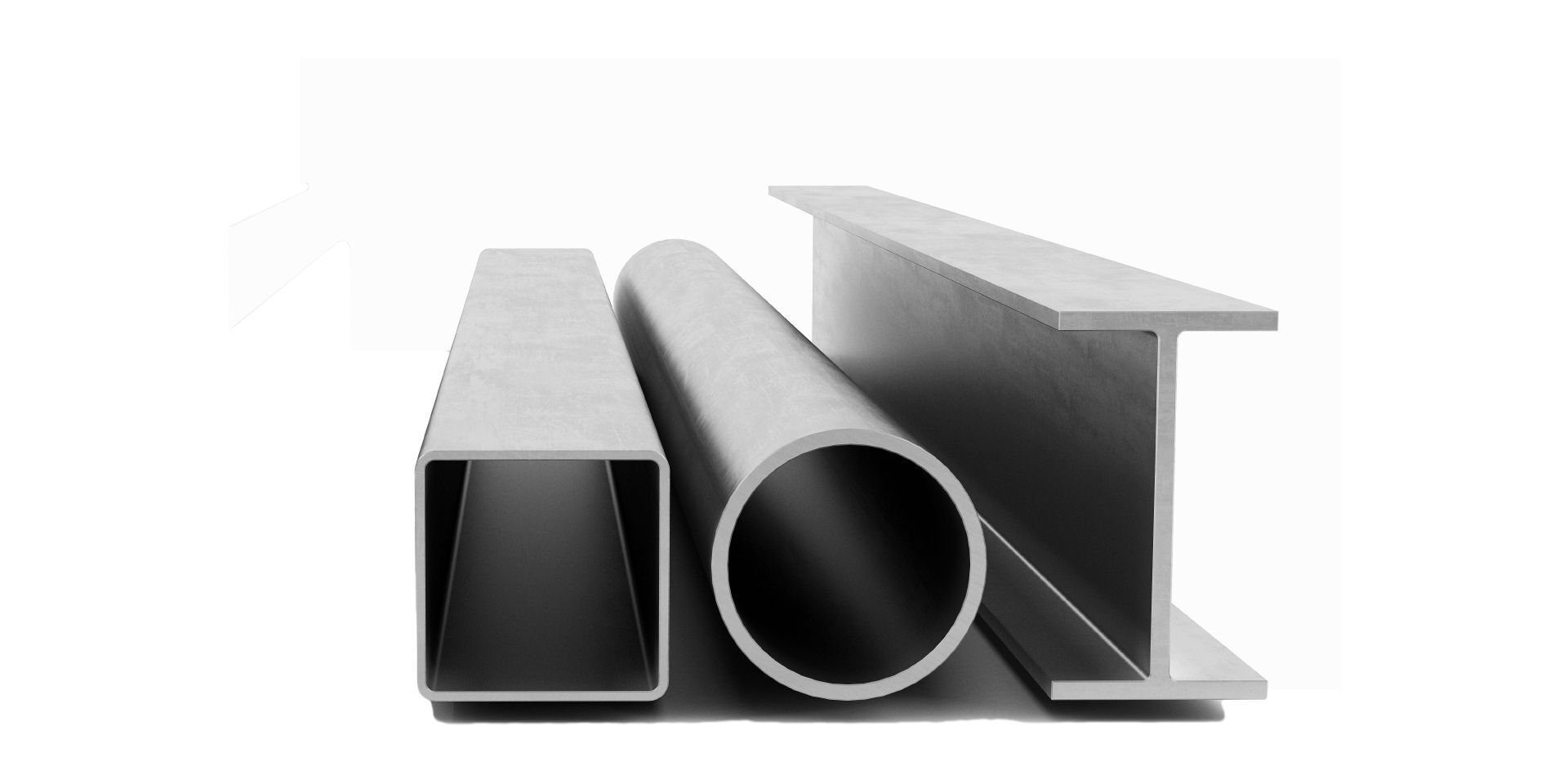

• Due to highly competitive loadings, reduces paint consumption thus saving costs and throughput time. In addition to that, lower loadings enable faster overcoating of painted sections. Fontefire ST 60-1 provides efficient fire protection for constructional steelwork up to class R120 in the fire resistance classification. • As a one-component product easy to apply on site. The sagging value is very good and the paint can be applied to a smooth matt finish. The CE-marked Fontefire ST 60-1 is compatible with a wide range of primers and topcoats. The product is tested and approved in accordance with ETA. • Can be used in semi-exposed conditions (Type Y, EAD 350402-00-1106) without any topcoat. The paint is certified for ‘H’ or ‘I’ shaped beam and column sections as well as rectangular/circular hollow columns and rectangular hollow beams. • Has extremely low volatile emission compounds thus resulting in a safer working environment while meeting the most stringent environmental demands. • Recommended to be applied on-site during dry conditions. Components painted in workshops must be topcoated and properly dried before taken outdoors.

Highly competitive loadings

Due to highly competitive loadings, Fontefire ST 60-1 reduces paint consumption thus saving costs and throughput time. In addition to that, lower loadings enable faster overcoating of painted sections.Fontefire ST 60-1 provides efficient fire protection for constructional steelwork up to class R120 in the fire resistance classification.

Great application properties

As a one-component product, Fontefire ST 60-1 is easy to apply on site. The sagging value is very good and the paint can be applied to a smooth matt finish. The CE-marked Fontefire ST 60-1 is compatible with a wide range of primers and topcoats.

Suitable for semi-exposed conditions

Fontefire ST 60-1 can be used in semi-exposed conditions (Type Y, ETAG 018) without any topcoat. The paint is certified for ‘H’ or ‘I’ shaped beam and column sections, rectangular/circular hollow sections as well as rectangular/square hollow beams.