Temadur 90

High gloss

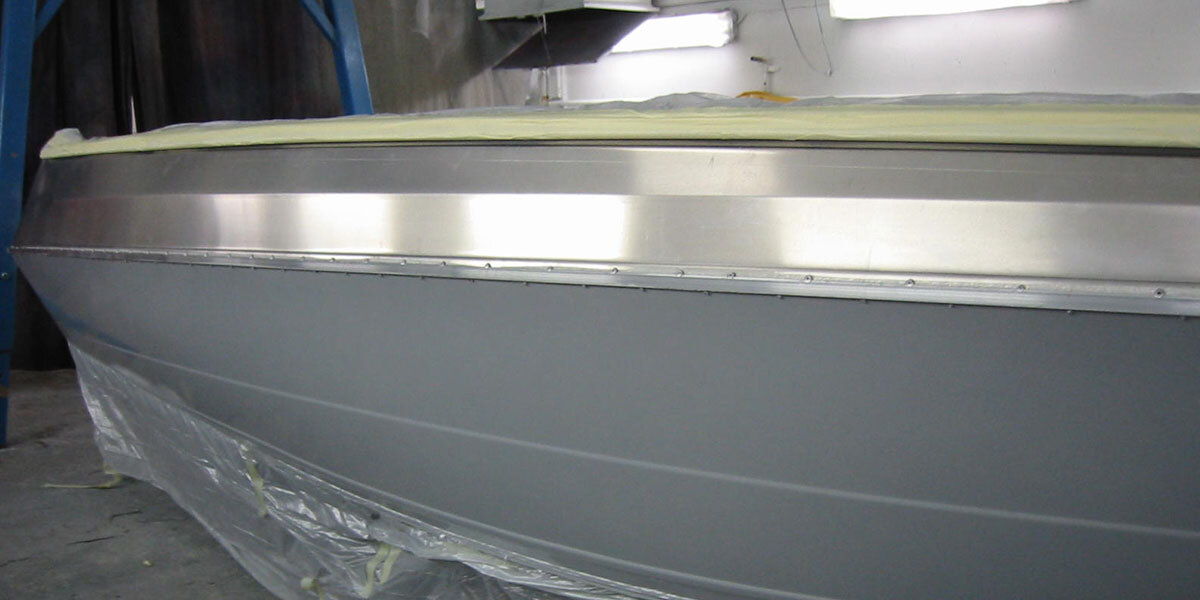

A two-component, high gloss polyurethane paint, hardener aliphatic isocyanate.

- Superior gloss and color retention

- Excellent weathering and abrasion resistance

- Can be used for wooden surfaces

A two-component, high gloss polyurethane paint, hardener aliphatic isocyanate.

Product Features

• Forms a durable, easy-to-clean and non-chalking topcoat with outstanding gloss and colour retention. The paint has an almost unlimited range of colors, including metallic effects. • Outstanding resistance to weathering and abrasion makes the product a very good solution for original equipment manufacturing, such as agricultural machinery and haulage equipment. • Temadur 90 can be used for interior wooden surfaces, e.g. metallic shades kitchen doors. • Recommended to be used as a glossy decorative finishing coat for epoxy systems on a variety of substrates such as steel, aluminium, concrete etc. exposed to severe weathering and/or chemical stress. • Due to CE marking can also be used on top of coating systems used for concrete surfaces. See page 3. • Hardener 008 7594 is recommended to be used in hot and humid conditions. • The product has been tested for non-contamination of grain cargo at the Newcastle Occupational Health & Hygiene, Great Britain.

Recommended Uses

• Recommended for painting of transport and haulage equipment, storage tank exteriors, steel framework and other steel structures, machinery and equipment.

Superior gloss and color retention

Temadur 90 forms a durable, easy-to-clean and non-chalking topcoat with outstanding gloss and colour retention. The paint has an almost unlimited range of colors, including metallic effects.

Excellent weathering and abrasion resistance

Outstanding resistance to weathering and abrasion makes Temadur 90 a very good solution for original equipment manufacturing, such as agricultural machinery and haulage equipment.

Can be used for wooden surfaces

Temadur 90 can be used for interior wooden surfaces, e.g. metallic shades kitchen doors.